BLOG

Key Trends & Challenges

in Supply Chain & Logistics

September 3, 2024 | 6 minute read

As it became increasingly vital for companies to modernise their supply chains, many supply-chain leaders are moving away from manual systems and outdated, legacy software, embracing next-generation systems incorporating machine learning and data analytics. However, digitalising and streamlining processes require a significant investment of human resources and time.

Resilience, a crucial characteristic of successful supply chain companies, is best exemplified by industry leaders like Toyota. These companies have consistently demonstrated how proactive strategies can effectively mitigate the impact of unforeseen events, instilling confidence in the effectiveness of such approaches.

Despite the significant challenges that supply chains faced in 2023, with less than 40% of organisations meeting their annual goals, the following year, 2024, was a testament to the remarkable resilience of supply chain professionals. Leveraging technology and experience, they adapted swiftly, showcasing their ability to navigate known and unknown uncertainties.

Facing Uncertainty

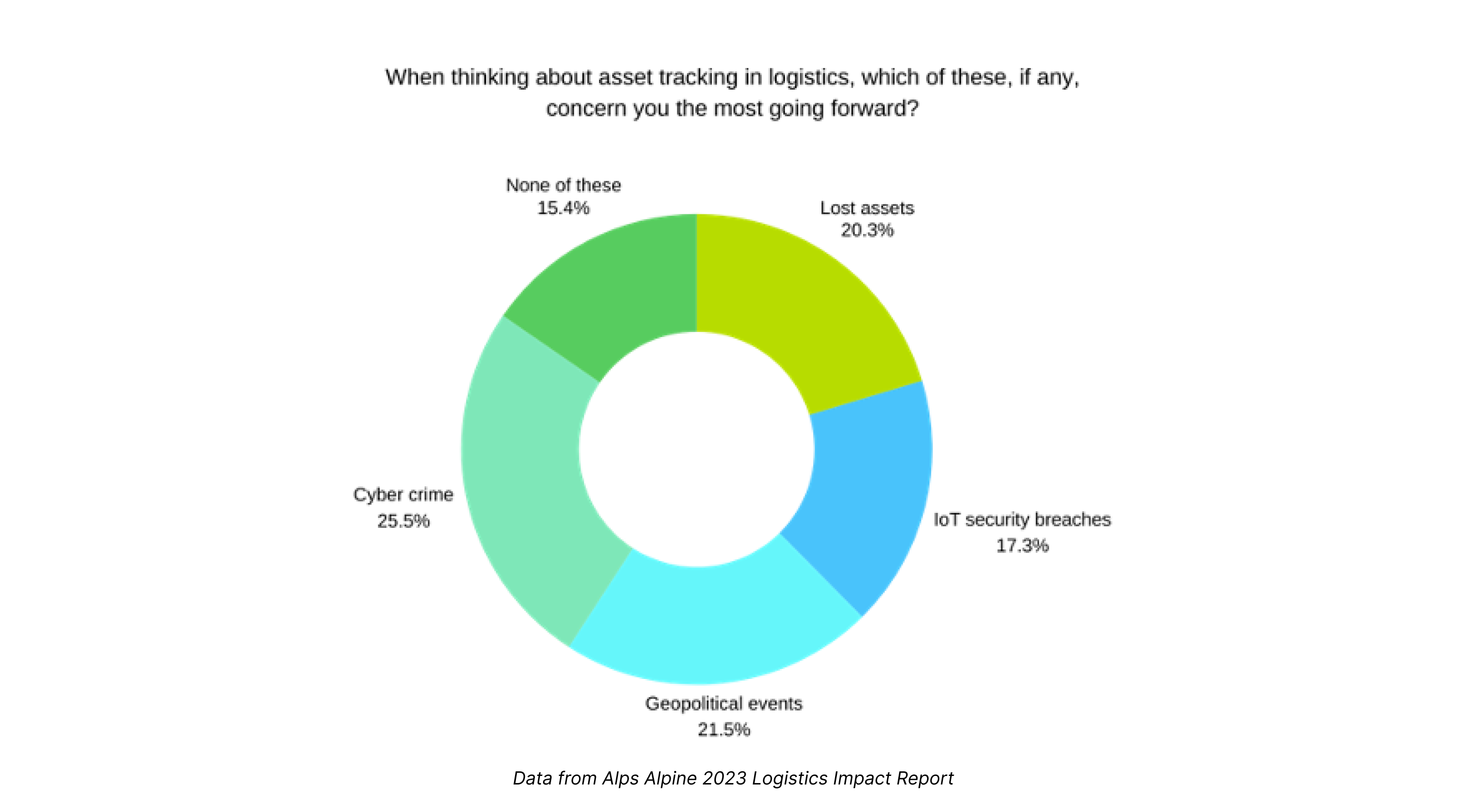

After last year, many organisations failed to achieve their business goals due to constant disruption, and 2024 has been nothing less challenging. As with other industries, supply chains also face serious impacts from global factors such as climate change, geopolitical conflict, and artificial intelligence and cybersecurity threats:

Geopolitical risk contributes to supply chain disruption, as seen in conflicts like the wars in Ukraine and Gaza, the US-China trade war, and the conflict in the Red Sea. These conflicts lead to increased costs and delays in supply chains.

Economic challenges and inflation have also impacted supply chains, especially during the pandemic. Lockdowns disrupted logistics operations, leading to increased production and transportation costs. Inflation rates, combined with geopolitical unrest, further impact supply chain costs.

Climate change poses another risk to global supply chains, with extreme weather events causing disruptions and rising costs. Resilience and collaboration with suppliers are essential to ensure operational continuity. Organisations must also comply with environmental, social, and governance (ESG) principles, which can require upfront investments and limit supplier diversification.

- The evolving cyber threat landscape is a significant concern for organisations and their third-party vendors. To fortify cybersecurity measures, organisations must vigorously evaluate data-sharing practices and collaborative partnerships with suppliers.

Top Trends & Challenges

In 2024, most of the trends and challenges that supply chain leaders anticipate are primarily technology-driven. It's clear how, without foundational elements like data management, new technology may worsen the existing process issues. Additionally, a lack of collaboration within and outside supply chains remains a persistent challenge for the third consecutive year. In a supply chain framework, lack of cooperation can prove particularly detrimental, leading to disruptions that affect customers' receipt of orders in a timely, intact, and properly documented manner.

There are several challenges in asset tracking. One of the main technical challenges we are dealing with is the lack of a globally unified standard for connectivity and data communications in our industry. Asset tracking requires solutions that can work seamlessly across different regions, technologies, and environments. However, due to the adoption of various standards and technologies in different regions, achieving reliable and widespread coverage often requires the use of hybrid, multi-network architecture. Although there is a growing trend towards convergence, achieving global harmonisation of spectrum policies and technology standards remains difficult.

Moreover, the current economic situation, characterised by high inflation, supply chain disruptions, geopolitical conflicts, and the looming threat of recession, is having a significant impact on the asset-tracking market. This has made many of our customers cautious about making large capital expenditures for digital transformation initiatives. As a response, we have adjusted our pricing models to include more subscription and pay-as-you-go options to reduce upfront barriers.

Sustainability has also become an increasingly important focus in our industry, with companies setting ambitious environmental targets, leading to a growing demand for refurbishment programs instead of simply disposing of hardware assets at the end of their life. At Alps Alpine, we're committed to sustainable practices throughout our operations. Our Asset Logistics Inventory & Rotation (ALIR) system features a dedicated sustainability Key Performance Indicator (KPI), allowing us to track and improve our environmental impact. We've set ambitious goals, including achieving carbon neutrality across all operations by 2050 and transitioning to 100% renewable energy in all our manufacturing sites by 2030. We're already making strides towards these targets; our ALIR factory currently runs on 100% renewable energy, setting a benchmark for our other facilities. To further reduce waste and resource consumption, we've implemented a comprehensive refurbishment and battery replacement program, significantly extending the service life of our devices. Through these initiatives, Alps Alpine is not just talking about sustainability – we're actively working towards a greener future in the asset tracking and logistics industry.

In terms of technology, there is a lot of excitement around topics such as artificial intelligence and machine learning. While these technologies have the potential to enhance areas like predictive analytics and autonomous decision-making, truly transformative AI/ML applications in logistics and asset tracking are still being developed.

Moving Forward & Positioning Your Organisation For Success

Over half of organisations (56%) anticipate an increase in their 2024 budgets for supply chain management tools, technology, innovation, and initiatives compared to last year. Current trends—inside and outside the supply chain and logistics—are compelling companies to reevaluate how they measure and track data, optimise their processes, and choose technology.

To excel in this competitive landscape, we advise leveraging analytics, enhancing digital capabilities, strengthening data management practices, staying ahead of external factors like technological advancements and regulatory changes, empowering collaboration and fostering innovation as a core strategy. By prioritising these areas, you will be better equipped to meet organisational objectives and navigate uncertainties effectively. As mentioned in the beginning, resilience is crucial for the success of your business. When you can anticipate changes in the operational environment, you can safeguard operations while exploring innovative pathways for growth and development in a globally interconnected ecosystem. These strategies hold the promise of not just surviving but thriving in the future of supply chain management.

One way to strengthen your supply chain is to utilise advanced analytics and embrace increased supply chain data management for informed decision-making. Begin by building the foundations, such as automating the supply chain and optimising inventory, warehouse, and transportation management with asset tracking management. When you can monitor your assets, you can easily manage and optimise them. This is the fundamental essence of asset tracking and its importance in the digitalisation of the supply chain.

Scalability and integration capabilities of the asset tracking system are critical parameters, especially when speaking with big customers, OEMs, and governmental bodies as customers. However, these are not the only factors that matter. Reliability and durability are key must-have standards when choosing the right solution provider (from the customer's perspective). When it comes to customers like DHL who purchase significant volumes of our trackers, delivering this important volume on time and always keeping the same quality are crucial.

Integration capability with existing customer systems or the ability to communicate with customer systems is also crucial from a customer perspective. We have a proven track record of successful integrations with existing systems, including those of large corporations that often cannot make significant changes to implement external solutions.

Want to know more about asset tracking and how it can transform your supply chain strategy? Download our research now and learn how to boost your productivity, efficiency, and sustainability.

Sources:

- https://www.apqc.org/

- https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/tech-enabled-business-transformation-the-trillion-dollar-opportunity/what-can-i-do/supply-chain-management

- https://www.forbes.com/sites/stevebanker/2023/04/09/digital-transformation-in-supply-chain-management/?sh=7ab6301e8331

- https://www.imd.org/ibyimd/2024-trends/five-supply-chain-trends-for-2024/

- https://www.dhl.com/gb-en/home/insights-and-innovation/insights/logistics-trend-radar.html

Contact us!

Got questions? Book a demo and get the answers you need.

Discover how ALPS ALPINE asset trackers can support your operations, with no pressure or obligation to purchase.

Fill out the form below to connect with our team.